Air Chain Hoists & Trolleys

How to Determine Your Air Hoist Requirements

Air Hoist Capacity

- Determine the maximum load to be lifted

- If the load falls between standard rated capacities, always select the higher capacity (i.e., for 4,300 lb. maximum load, use 6,000 lb., or 3-ton capacity hoist)

Hoist Lift

- To determine the total lift required, measure the distance from the bottom of the beam to the lowest point on the floor to be reached and subtract the hoist headroom dimension shown in the specifications.

- The remaining distance is the lift required on the hoist.

- Always select a standard lift equal to or greater than the distance.

Duty Cycle

- Air motors inherently are self-cooling during operations.

- Unlike an electric motor which heats during operation, air motors are suitable for unlimited “on-time” and unlimited “number of starts”.

- Most all air chain hoists are desirable for duty cycles demanding 100% “on-time”.

Explosive Atmosphere

- Since air chain hoists operate on compressed air, there is no electrical arcing hazard to cause explosions in such areas as paint spraying and petrochemical facilities.

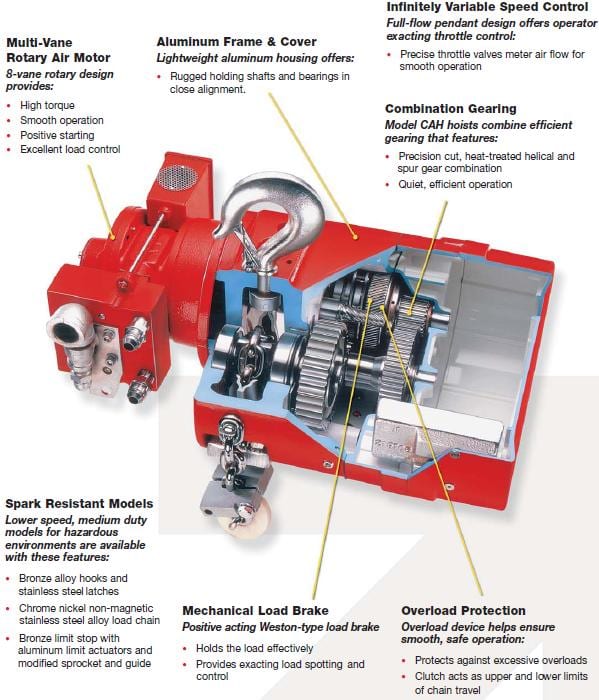

- For those hazardous atmosphere applications where resistance to friction sparks is vitally important, spark resistant models are available.

- Spark resistant features include: bronze alloy hooks, stainless steel hook latches, non-magnetic, stainless steel load chain; modified load sprocket, guide and stripper arrangement; and stainless steel or anodized aluminum lower blocks.

- Since stainless steel load chain is of lower strength than standard, spark resistant air chain hoists are usually de-rated in capacity.

Control

- Normally, air hoists lift loads at a faster rate of speed than electric hoists.

- Additionally, air hoists have variable speed control to lift loads from creep speed to full speed.

- Applications requiring variable speed lifting for precise load spotting and smooth starting action should employ an air hoist.

- Other options to be considered as a means for operator control of the air chain hoists and load are pull cord and pendant throttle.

Air Hoist Suspension

- Air chain hoists can be offered in a wide variety of suspension options.

- Hook type suspension offer maximum versatility and portability in most environments.

- Lug suspensions save headroom and can be used with rigid mount trolleys or in permanently mounted locations.

Trolley Type

- There are three standard trolley types that can be used to suspend air hoists

- Push Trolley – Recommended for light capacities up to 2-tons and lifts below 20 feet. Most economical solution.

- Hand Geared Trolley – Offers precise control for load spotting. Most favorable for higher capacities, short monorails, and where lifts exceed 20 feet.

- Air Motor Driven Trolley – Most widely used method of suspension, particularly 2-ton capacity and above. Often a necessity where long monorails are used.

Special Note

- The installation of every air hoist must include a filter and lubricator in the air line. An air regulator is also recommended.

Cutaway View of Coffing CAH Large Frame Air Hoist

Download – Coffing CAH Large Frame Air Hoist Brochure

Download – Coffing CAH Small Frame Air Hoist Brochure

Download – Coffing SLA Model Air Chain Hoist Brochure

Download – Coffing AMT Model Air Hoist Motor Trolley

Beaton Industrial sells and distributes Air Hoists and Air Hoist Parts throughout the United States. Beaton Industrial provides air hoist service, inspections, and installation services throughout New York state including the cities of Utica, Syracuse, Watertown, Binghamton and Albany New York. If you would like to speak with a air hoist representative, please Contact Us today!

Some of the information presented on this page comes from the Coffing Hoist General Catalog copyright 2010 by the Columbus Mckinnon Corporation. To download a full length catalog, please click here!