Curb Angles vs. Pit Kits vs. Pour in Pans

Dock Leveler Installation Methods

There are three main installation methods available for both mechanical and hydraulic dock levelers. The first method is a preformed pit utilizing steel curb angles, the second is known as the pit-kit method, and the third is a pour in pan option (a.k.a. pour in place method).

Depending on the application, all three methods have their advantages.

Preformed Pits using Curb Angles and Wood Forms

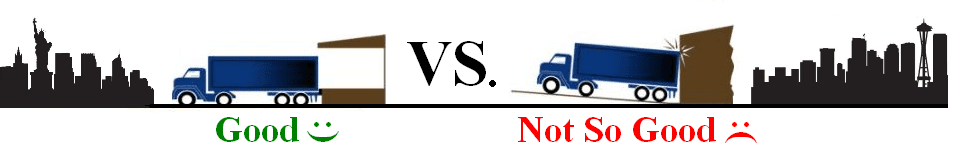

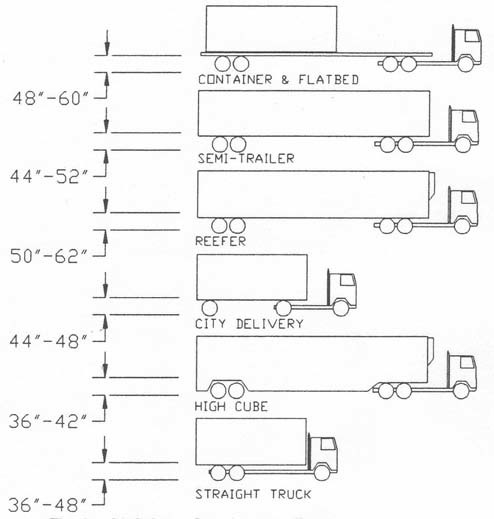

With this method, dock levelers are are installed into pits that are formed into the concrete floor ahead of time. These preformed pits are sized to suit the specific dimensions of the dock leveler selected for the building application. Choosing the preformed method allows the building floor and loading dock area to be poured according to the contractors timeline. There is less of an initial equipment cost associated with a preformed pit leveler. However, they require more time and labor to form the pit and install the dock leveler. With that said, preformed pit mounted levelers are generally more costly in the long run vs. pit-kit or pour in pan levelers.

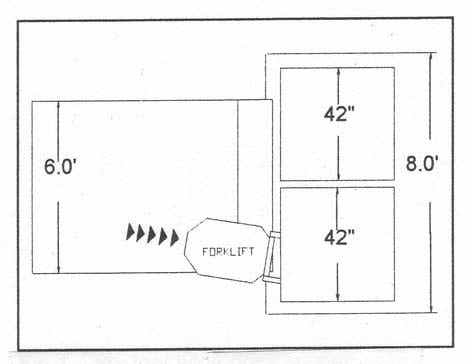

The Curb Angle and Wood Form method uses steel angles supplied by the concrete contractor or shipped ahead of the leveler from the dock manufacturer. The concrete contractor will place the angles at each ledge of the pit to help keep the concrete floor from crumbling on the corners during use. The concrete contractor will build wooden forms to frame the pit to the desired size. See the picture below.

Preformed Pits using a Pit Kit

A pit-kit is a set of pre-fabricated steel panels that are bolted together on site to yield a true square pit for less money than traditional wood forms. Pit kits include the 3 side walls shown below and the front curb angle. The pit kit is bolted together at the corners to form the rectangle. Next, a couple of pieces of wood are placed on top and bolted to the steel. This ensures the steel walls will not move or collapse inward when the concrete is poured around the outside. When the concrete is set, the installer cuts the bolts from the wood supports, and grinds them smooth to the top of the pit kit curb angle. Once all concrete is dry, the pit is ready to receive the dock leveler.

Pit Kit Being Installed. | Photo Credit: Perma Tech

Pour In Pans

Pour in Pans are similar to pit kits except the steel walls come welded to the dock leveler. This solution is ideal for locations installing multiple units at one time. With this method, a notch is cut in the foundation wall for the leveler to be positioned into prior to the floor being poured. A concrete slab is made to match the height of the opening in the foundation wall. The slab will be used for setting the leveler on once it arrives. Once the dock leveler arrives on site, it is set on the slab and centered. The last step is to pour concrete around the outside of the pour in pan. The pour in pan walls protect the leveler from the concrete, and also allow for a perfectly formed pit.

Dock Leveler Pour in Pan | Photo Credit: Allied Solutions

If you have any questions about your particular application, please reach out to our Sales team, 315-797-9346.