American Scissor Lift Tables

If you are looking for an American made Hydraulic Scissor Lift, look no further than Advance Lifts. You’ll receive a 100% made in America scissor lift table to handle the most brutal workplace conditions. They come standard with the best warranty in the industry, 10 years / 250,000 cycles. Hydraulic scissor lift tables are a time-proven method to move heavy objects from one height to another and have proven to increase productivity while reducing worker injuries.

Production (P) Series Scissor Lift

- The P Series is the most popular model in the Advance Lifts Lineup

- Capacities range from 2500 lbs to 6000 lbs on the standard table

- Platform sizes range from 24″ x 36″ to 72″ x 120″

- Lowered Heights as low as 6.5″

- Raised Heights as high as 70″

- Travel varies from 24″ to 60″

Double Wide (DW) Hydraulic Lift Table Configuration Rules:

- The units making us a double wide lift table must be of equal capacity and travel, and must have the same width and length base frame.

- DW capacity equals the catalog capacity of a single unit, times 160%

- DW travel equals the travel of the base unit less 2″.

- The double wide scissor lift table lowered height equals base unit lowered height + 2″.

- The maximum platform width may be up to 24″ wider than the sum of the minimum platform widths of the base units.

- The maximum platform length may be up to 24″ longer than the minimum platform length of the base unit.

- Double wide hydraulic lift table side loads equal (the base unit side load x 2) x 60%.

- Side load capacity is reduced by 2% per inch increase over the minimum platform width of the DW unit.

- DW end load capacity is twice the capacity for a single unit.

- Lift table end load capacity is reduced by 2% per inch increase over the minimum platform length of the base unit.

Double Wide Specifications

- Capacities from 4,000 lbs to 12, 000lbs

- Platforms from 48″ x 36″ to 120″ x 120″

- Lowered Heights from 8.5″ – 12″

- Raised Heights from 30.5″ – 70″

- Travel Distances from 22″ – 58″

Double Long (DL) Hydraulic Lift Table Configuration Rules:

- The lift tables making up a double long (DL) lift must be of equal capacity and travel, and must have the same width and length base frames.

- DL lifting capacity equals twice the catalog capacity of a single lift provided that the platform is no longer than twice the length of the maximum platform allowed for a single unit.

- Factory engineers will reduce the capacity for units with extra long platforms. Consult your sales rep for exact capacities – 800-724-4052.

- DL travel equals the travel of the base lift.

- The minimum platform length is (2 x base frame length + 2″).

- DL side load capacity equals twice the base unit side load capacity.

- Side load capacity is reduced by 2% per inch increase over the minimum platform width of the base unit.

- DL scissor lift table end load capacity is the same as the base unit end load capacity.

- End load capacity is reduced by 2% per inch increase over the minimum platform length of the double long hydraulic lift table.

- Lowered height may increase for applications where the platform is not evenly loaded (contact Beaton for specific applications)

Double Long Specifications

Double Long Specifications

- Capacities from 4,000 lbs to 12,000 lbs

- Platforms from 24″ x 74″ — 72″ x 336″ (28 feet long!)

- Lowered Heights from 6.5″ – 11″

- Raised Heights from 30.5″ – 71″

- Travel Distances from 24″ – 60″

Double High (DH) Hydraulic Lift Table Configuration Rules:

- Multi Stage Units, not to be confused with double-high units, cannot be stacked into DH units.

- The lifts making up a double high lift table must be of equal travel and both of their base frames must be the same width and length.

- The capacity of a DH Hydraulic lift table can only equal the capacity of the upper lift, when the lower lift capacity equals or exceeds the sum of the weight and capacity of the upper lift. If there is a shortfall in the capacity of the lower lift, this must be subtracted from the capacity of the upper lift to determine total unit capacity.

- The double high platform lift travel is equal to the sum of the travel of the upper and lower units.

- The maximum platform size may be up to 12″ wider than the minimum platform dimension and no longer than the maximum listed platform length for the upper table.

- The end load and side load capacity is equal to one half of the upper lift end and side capacity.

- Side load capacity is reduced by 4% per inch increase over the minimum platform width.

- End load capacity is reduced by 4% per inch increase over the minimum platform length.

- DH units with total platform travel over 72″, should use guide angles to reduce potential sway during loading and unloading operations.

- If personnel are going to ride the units, then handrails, gates and interlocks should be considered and local safety codes should be investigated.

- Scissor lift tables with internal power units will continue to have internal power units when they are stacked.

- The speed of the stacked hydraulic lift tables will equal the sum of the individual unit speeds.

Double High Specifications

Double High Specifications

- Capacities from 900 lbs to 10,500 lbs

- Platforms from 24″ x 36″ — 54″ x 84″

- Lowered Heights from 13″ – 24″

- Raised Heights from 61″ – 144″

- Travel Distances from 48″ – 120″

Heavy Duty (HD) Series Scissor Lift Table

The HD-Series Scissor Lift was designed for higher capacity applications beyond the scope of the P-Series units. Included in the design is a patented “platform centering device”, which has been shown to triple the life of the lift. All controls are Underwriter Laboratory approved. The lift tables are fully primed and finished with a baked enamel finish. The hydraulic cylinders are machine grade with clear plastic return lines. All pressure hoses are double wire braid with JIC fittings. Hydraulic fluid reservoirs are made of mild steel for long lasting durability. All Heavy Duty series lifts conform to all applicable ANSI codes.

- Capacities from 8000 lbs to 12,000 lbs

- Double Wide from 12,800 lbs to 19,200 lbs

- Double Long from 16,000 lbs to 24,000 lbs

- Platforms from 30″ x 48″ to 78″ x 114″

- Double Wide from 84″ x 78″ to 132″ x 114″

- Double Long from 30″ x 98″ to 78″ x 194″

- Lowered Heights from 9.75″ – 12″

- Double Wide from 11.75″ – 14″

- Double Long from 9.75″ – 12″

- Raised Heights from 33.75″ to 72″

- Travel Distances from 22″ to 60″

Super Duty (SD) and JUMBO (JSL) Series Scissor Lift – American Custom Lifts

The SD-Series lifts were designed as a step up from the HD series. Many of these models are modified dock lifts so you will notice that the edge of loading capabilities are often a higher percentage of the lifting capacity than is typical for smaller lifts. The JSL series units are a sampling of some of the very large special lifts that Advance Lifts produce. If you have a very large lift requirement that does match up with one of our Jumbo units, please call us and we will be pleased to quote on your exact requirements.

Super Duty (SD) Specifications

- Capacities from 5,000 lbs to 20,000 lbs

- Double Long from 10,000 lbs – 30,000 lbs

- Platforms from 6′ x 8′ – 8′ x 12′

- Double Long up to 8′ x 24′

- Lowered Heights from 10″

- Raised Heights up to 78″

- Travel Distances equals 58″ on all Models

Jumbo Series (JSL) Specifications

- Capacities from 6,000 lbs to 60,000 lbs

- Platforms from 9′ x 12′ to 8’6″ x 50′ long

- Lowered Heights from 15″

- Raised Heights up to 132″

- Travel Distances from 58″ to 99″

Pallet Lift Table – Palletizers

Advance Lifts, a leader in manufacturing American Scissor Lift tables, now offers a series of Pallet Lift Tables, also known as palletizers. Among the new lineup includes a Pneumatic, Mechanical (spring actuated), and Electric / Hydraulic pallet scissor lift.

Pneumatic Self Leveling Pallet Lift Table – Palletizer

This is a free-standing clutter free pallet lift table that needs no control lines or electrical lines to operate. This table allows the operator to simply set the air pressure gauge to the desired pressure and begin loading or unloading pallets. Available for pallet capacities up to 4,000 lbs.

This is a free-standing clutter free pallet lift table that needs no control lines or electrical lines to operate. This table allows the operator to simply set the air pressure gauge to the desired pressure and begin loading or unloading pallets. Available for pallet capacities up to 4,000 lbs.

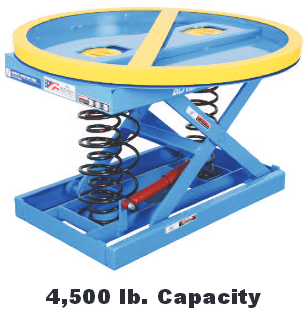

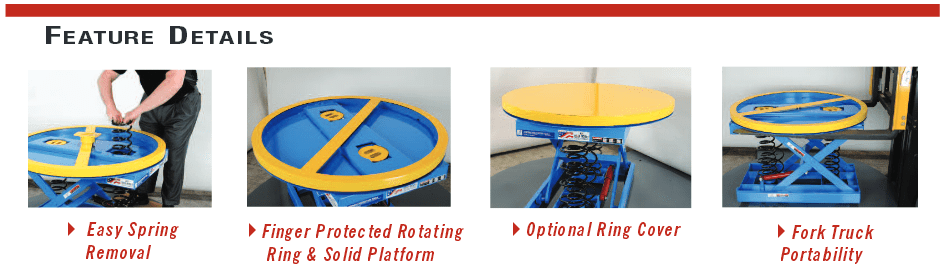

Mechanical Self Leveling Pallet lift – Model SL-S Series

This free-standing clutter free pallet lift table needs no electrical lines or control lines to operate. The operator simply selects the appropriate spring set and then begins palletizing or depalletizing the goods.

This free-standing clutter free pallet lift table needs no electrical lines or control lines to operate. The operator simply selects the appropriate spring set and then begins palletizing or depalletizing the goods.

Electric/Hydraulic Pallet Lift Table – Model PL-2524 & PL-4024 Series

When exact vertical positioning is an absolute must, the professionals choose an Electric / Hydraulic palletizer for their ergonomic needs. Comes standard in 110V, and can plug in anywhere!

When exact vertical positioning is an absolute must, the professionals choose an Electric / Hydraulic palletizer for their ergonomic needs. Comes standard in 110V, and can plug in anywhere!

Call Us For Up To Date Pricing 800-724-4052

Click the highlighted link if your are looking for the original American Scissor Lift Service Operation Manual.

Beaton Industrial sells, services, and installs American Scissor Lift Tables throughout New York State and nationwide. If your company is located in and around the cities of Utica, Syracuse, Binghamton, Ithaca, Watertown, Albany, Poughkeepsie, or Plattsburgh, New York; Contact Beaton Industrial today to arrange a meeting with one of our Lift Table representatives.