Jib Crane Design

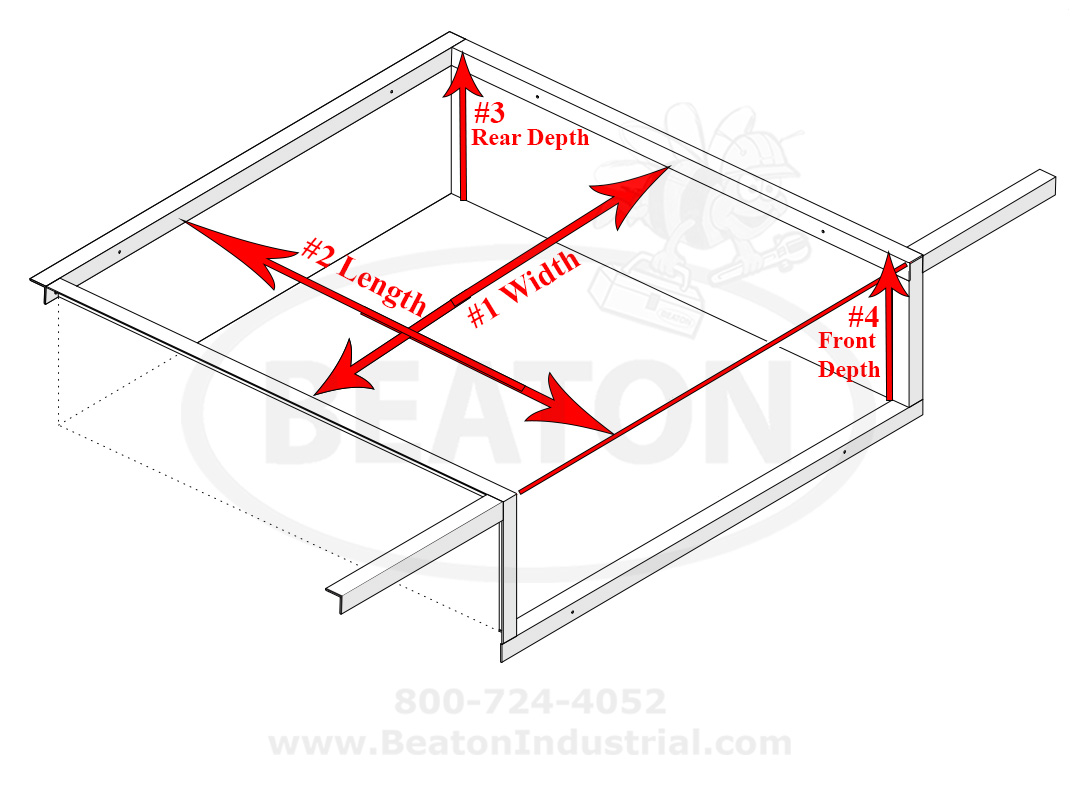

I’ll need just 3 pieces of information to provide you with pricing and a set of drawings.

- The height under boom (a.k.a. HUB)

- The span

- The Capacity

If you have those 3 pieces of information, submit your jib crane design request.

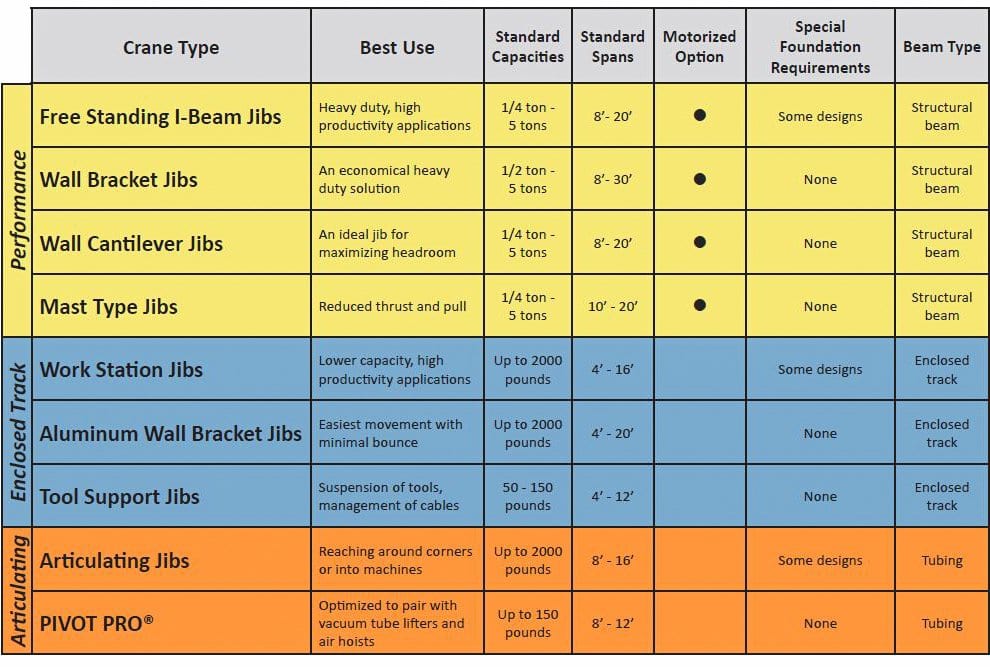

There are 9 different types of Jib Crane Design. See the list below.

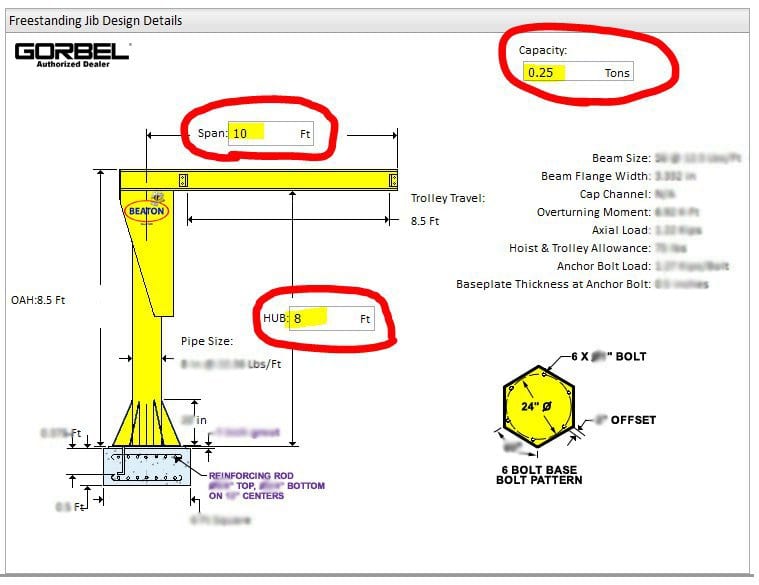

1) Free Standing Jib Crane

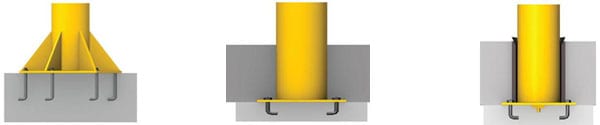

This is probably the most common jib crane found in factories across globe. The free standing system mounts via 3 different options.

- The first and most common option is Baseplate Mounted, where the bottom of the jib has a baseplate that secures to the concrete floor via 6 bolts.

- The second option is a permanent mount called the insert mount. With this style, the jib column is mounted within the concrete floor for a permanent solution.

- The last option is called an “insert sleeve mounted” jib crane. This option provides a separate steel sleeve that is also permanently installed in the concrete floor. The only difference being that this option allows the jib to be slid into the sleeve, and removed very quickly and easily.

2) Articulating Jib Crane

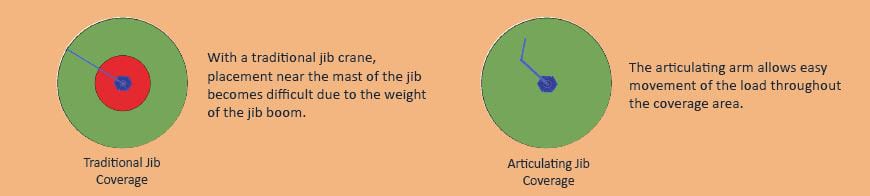

Articulating jib cranes provide the ability to position loads in places you cannot reach with traditional jibs.

- Ease of Movement – Ideal for work cells where the load must be picked or placed near the location of the mast. Traditional jibs can be strenuous to pivot when the bundle is on the inner part of the beam.

- Precise Positioning – Unique pivoting action allows for the articulating jib crane to be used in a wide variety of applications, such as the loading dock shown below.

- No Shortage of Options – With spans available up to 16′, and capacities up to 2000 lbs., the articulating jib can be tailored to fit just about any need.

3) Workstation Jib Crane

Workstation Jib Cranes provide excellent coverage in work cell areas not properly accommodated by a central overhead crane. These cranes are ideal for hanging air balancers, hoists, vacuum lifters, and tool balancers.

- Clean Movement – The Work Station Jib Crane comes equipped with a high strength enclosed track design. The enclosed track keeps the hoist trolley rolling surface clean. This grants easier movement, and extended life of the trolley and rail.

- Rotates with Ease – The enclosed track weighs less than a traditional I-Beam crane, making for smooth rotation.

- Make it Stainless – The work station jib can be outfitted in stainless steel for the 250 & 500 lb. capacities.

- Portability – Adding a portable base to the work station jib allows the unit to be moved via lift truck to multiple locations.

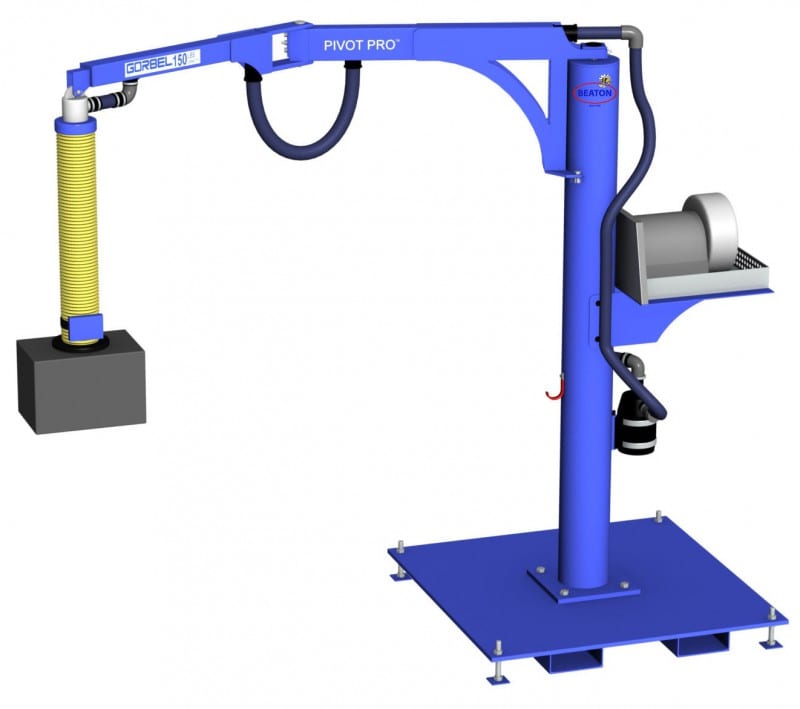

4) Pivot Pro – Articulating Jib Crane

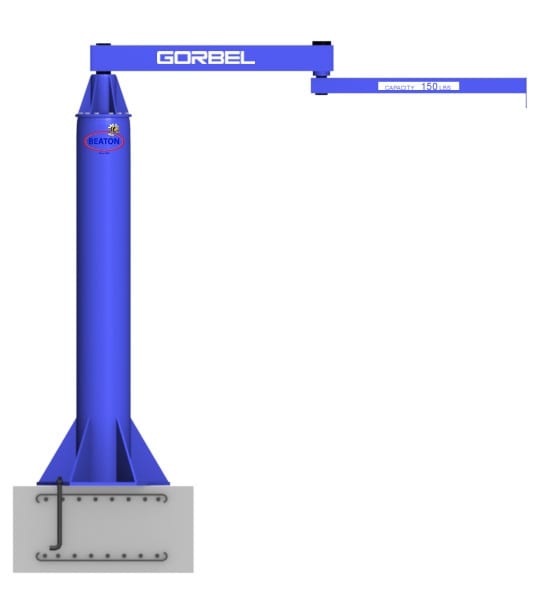

Designed specifically for applications under 150 lbs, the Gorbel Pivot Pro Jib Crane is less bulky and easier to maneuver.

- Rapid Return on Investment – The Pivot Pro provides a quick ROI thanks to it’s ergonomic design that’s responsible for increased productivity, reduced injuries, and improved safety.

- No Foundation Required – The Pivot Pro Jib Crane can be installed on any 6″ reinforced concrete floor, or used in conjunction with a portable base as shown in the picture.

- Sealed Tube – The Gorbel sealed tube gets rid of the need for vacuum festooning. Not only does this allow for greater travel, it also minimizes the chance of reduced suction caused by kinked hoses.

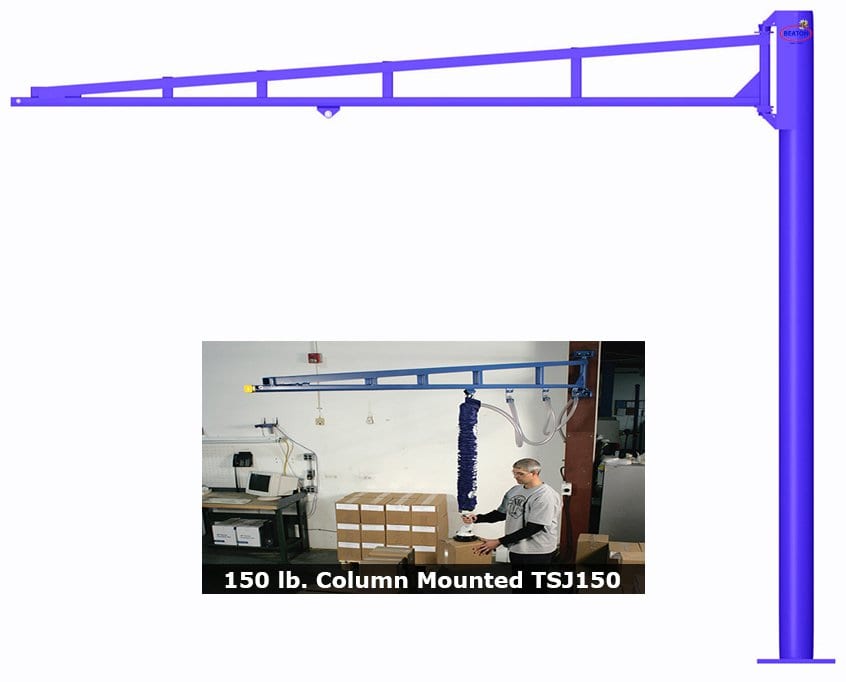

5) Tool Solutions Jib Crane

The tool solutions jib was designed for just what it sounds like, to provide an ergonomic and efficient solution for using tools in work cells. The jib is available in 50 lb. and 150 lb. capacities.

- Easy Movement – The TSJ50 (shown in picture below) is designed for light loads. The tie rod style jib insures high performance via the easy movement of a lightweight jib crane.

- Easy Adjustments – The boom is mounted to the jib column via four-bolt bracket. The bracket provides for easy adjustment of the boom height.

- Free Standing Or Wall Mounted – Have it your way, whichever way that is. The beauty of the adjustable bracket is that it is designed for mounting to either the free standing column, or a set of wall brackets. If the unit is ordered as a free standing system, all you have to do is purchase a set of wall mounting brackets to make the conversion. The reverse is also possible, and allows for a wall mounted unit to become a free standing unit.

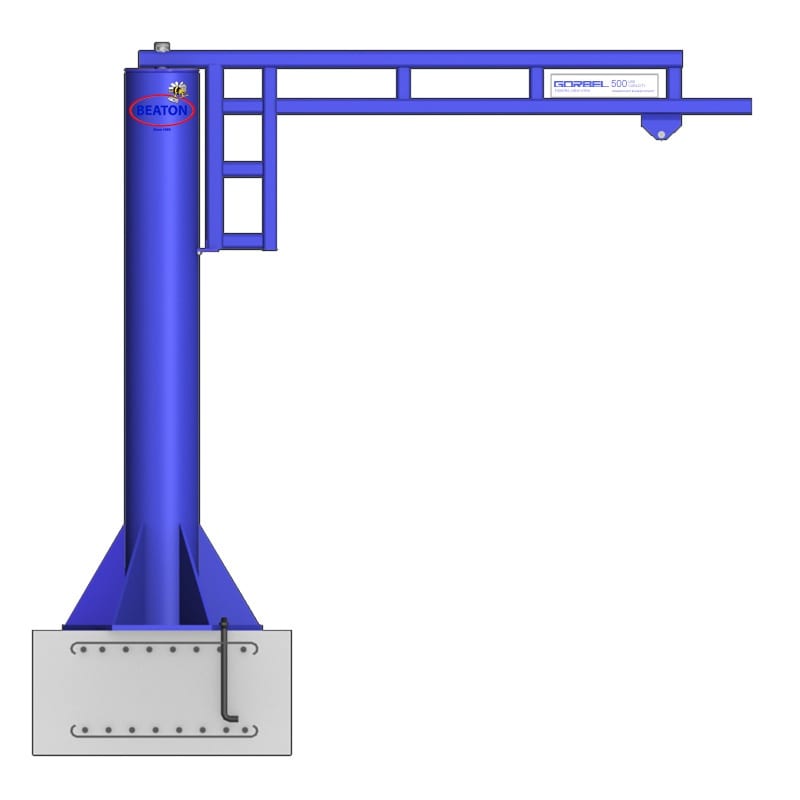

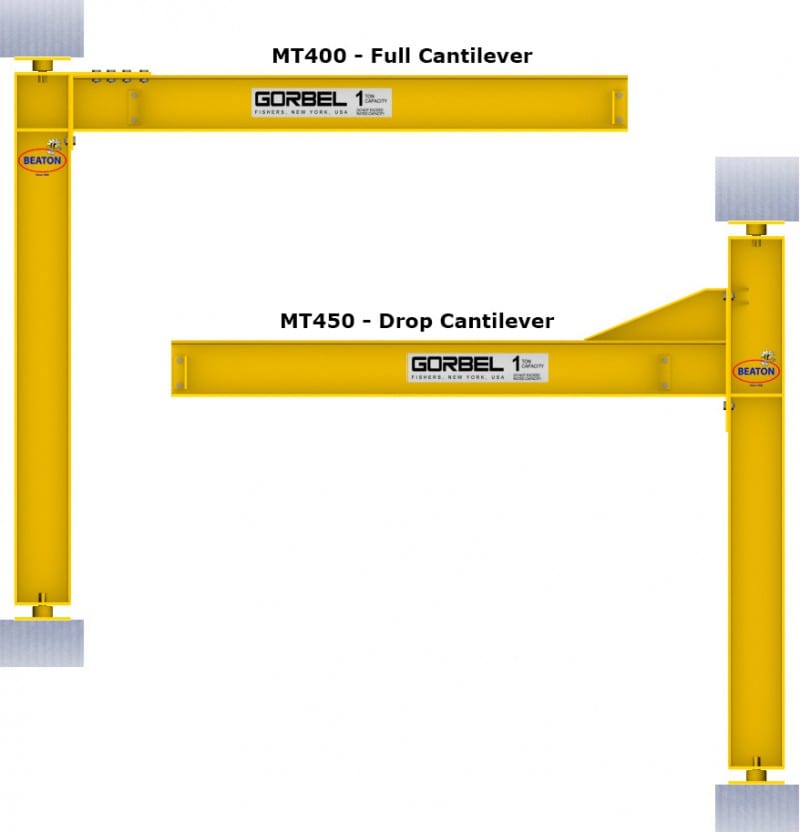

6) Mast Type Jib Crane

Gorbel’s Mast Type Jib Crane requires no foundation. The crane is floor supported, top stabilized, and rotates a full 360 degrees via a bottom and top bearing assembly.

- Economical – The simple design usually requires no special foundation. Making it one of the most cost effective 360 degree rotation jib cranes.

- Maximum Trolley Travel – Unlike some inferior designs, the Gorbel Mast Type Jib Crane uses a mast to beam connection that gets rid of the need for tie rods or knee braces, allowing for maximum trolley travel.

- No Headroom, No Problem – The full cantilever design allows for maximum lift and use of available headroom. The MT450 Drop Cantilever allows the jib boom to be placed at a precise height to clear overhead obstructions.

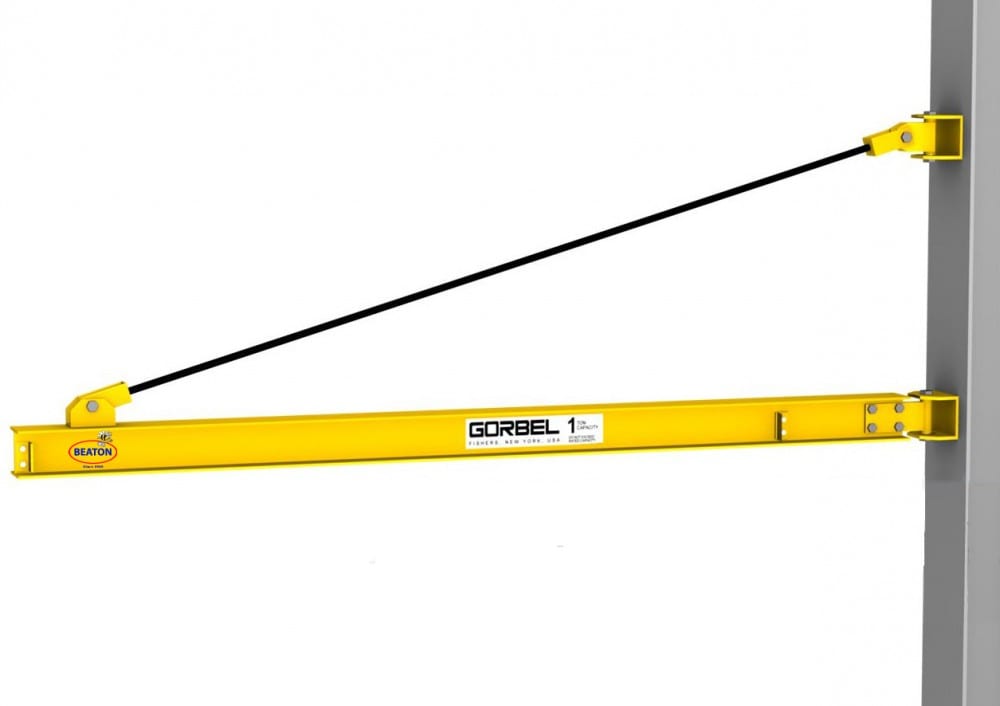

7) Wall Cantilever Jib Crane

Designed for use around bays, along walls or columns, or as a compliment to an overhead crane system. The Wall Cantilever Jib provides 200 degrees of hoist coverage. Keep in mind two key requirements must be met before installing the wall cantilever jib crane. 1st – The wall or column must be deemed structurally adequate for the capacity and forces that will be applied. 2nd – Ample clearance should exist above the boom throughout its rotation.

- Maximum Lift – Installing the wall cantilever jib very close to the underside of the lowest ceiling obstruction allows for maximum lift.

- Power Rotation – If your application requires it, this jib crane can be motorized for a powered rotation vs. the standard push /pull option.

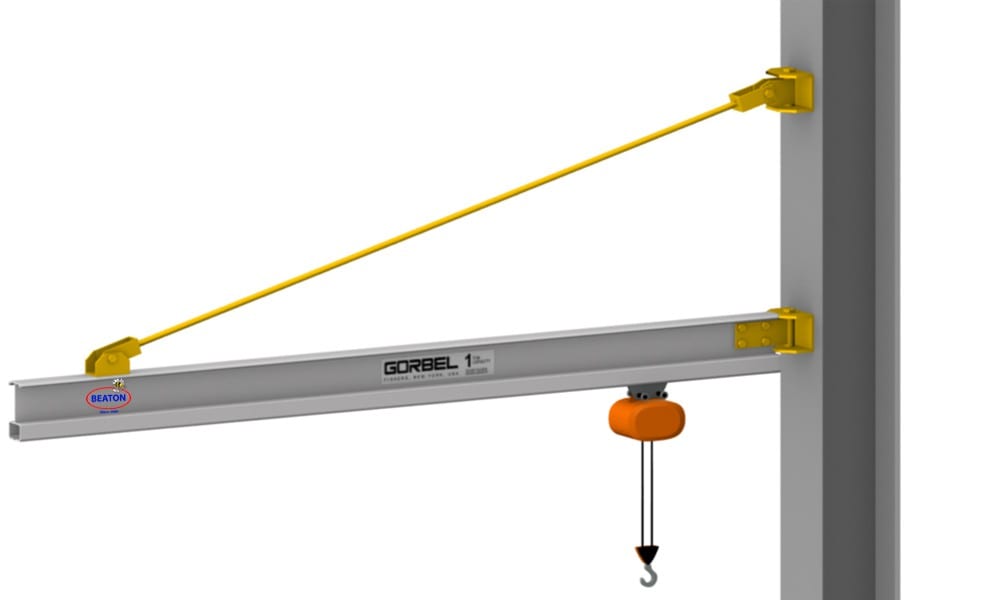

8) Wall Bracket Jib Crane

The Gorbel Wall Bracket Jib Crane design in geared to be an economical option for providing hoist coverage over work cells, and against walls.

- Ease of Movement – A little different from the Cantilever style crane above, this jib has a low weight boom combined with oil-impregnated bronze thrust washers and bushings that provide for super easy rotation.

- Save the Money! – The wall bracket jib is available in the same exact capacities as the cantilever jib. The difference in the jib crane design is the following: The cantilever is designed for low headroom spaces that require maximum lift. The wall bracket crane can be used where there is plenty of headroom. Again, if headroom is not an issue, save the money and go with a wall bracket style jib crane.

9) Aluminum Wall Bracket Jib Crane

The Gorbel Aluminum Tie Rod Jib Crane is an ergonomic powerhouse if you will. The most obvious difference from the standard wall bracket jib is the aluminum boom. The aluminum track diminishes the dead weight of the boom by 56% to 68% compared to the traditional I-beam jib crane. The second big change is an enclosed track vs an I-beam flange.

- Enclosed Track Technology – Not only is the aluminum track much lighter than the traditional I-beam jib, but the enclosed track has been shown to make the horizontal trolley movement 40% easier than the standard I-beam jib crane.

- Up to 2,000 lbs at a 16 foot span – Capacities start 250 lbs, and go up to 2,000 lbs. Standard length spans include, 8′, 10′, 12′, 14′, and 16′. If you have a special application, please give a call to find out if we can accommodate your request, 800-724-4052.

As you can tell from the options above, jib crane design varies greatly. If you need help choosing which design is the best for your application, review the chart below. If you need any help or have any questions, contact our Sales team at 315-797-9346. We’ll be happy to help any way we can.

Thank you for stopping by! If you found this article helpful, please share it!