Loading Dock Vehicle Restraint Systems

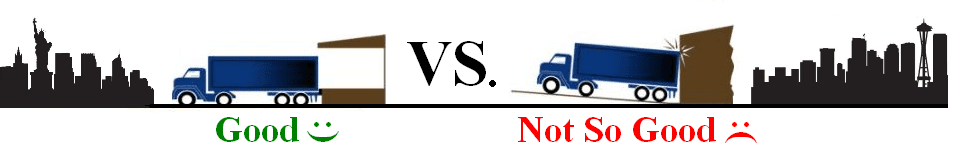

It happens at the best of loading docks. Vehicle creep. Unscheduled truck departures. Careless parking. In a busy shipping area, there cann be up to 100 opportunities per day, per single loading dock, for the most serious forklift mishap to occur.

The most common style of vehicle restraint is a face-mount design. Acting on the trailer’s ICC bar, it is an effective means of restraining the majority of the trailers. Face mount restraints have four main functions.

- Prevent premature trailer departure.

- Limit trailer creep away from the dock.

- Restrict trailer movement to keep the extended lip of the dock leveler in place on the floor of the trailer.

- Prevents trailer theft.

When selecting a face-mount vehicle restraint it is important to consider the operating range required, restraining capacity, and the flexibility needed to adapt to the wide variety of trailer ICC bars. The restraint must also be designed to withstand the environment in which it is installed; the location of the vehicle restraint is one of the harshest and least maintained in the average facility.

Normal operating range is from 12″ to 30″. Special designs can be made to accommodate unique applications requiring more range.

Face Mount Vehicle Restraint

Pull Away Force

Most vehicle restraints will offer a restraining capacity of 35,000 lbs. (i.e. it would take at least 35,000 lbs. of pull force to potentially cause the unit to release its hold).

Recessed Pit Vehicle Restraints

Some manufacturers offer a recessed vehicle restraint that store in a pit under the dock leveler. While effective, these units require an expensive storage pit to be constructed underneath the dock leveler.

Types of Vehicle Restraints

Face-mount vehicle restraints are available with various operating mechanisms. In most cases, the restraining arms of vehicle restraints are positioned by an electro-mechanical or an electro-hydraulic operating device.

Restraints are also available which are positioned manually by the dock attendant who uses a bar to both engage and disengage the restraining arms of the restraint.

Irrespective of the type of restraint installed at a dock, it is imperative that the operation – the engaging / disengaging of the restraint is easy and uncomplicated. A “user-friendly”, simple to use vehicle restraint will facilitate the regular use of the restraint by the dock attendant.

Face-mount vehicle restraints are easily installed and maintained. Because these restraints are externally mounted and easily installed, they are also readily relocated if necessary.

Hydraulic Vehicle Restraints

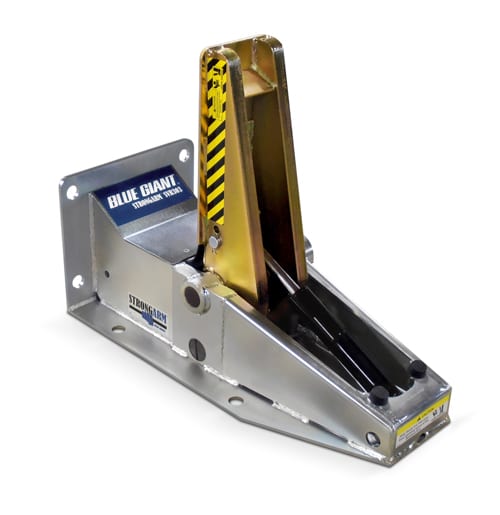

StrongArm SVR303

ANSI MH30.3 tested and approved, the StrongArm™ SVR303 is a low-profile, non-impact design with a rotating arm that seeks a trailer’s ICC bar via a patented, switch-less technology.

Once engaged, it uses 35,000lbs (15,909kgs) of restraining force to secure the truck to the dock. Dual-acting hydraulic cylinders prevent lock-up and release problems.

The Intelligent Positioning System (IPS) constantly communicates the location of the restraint arm via a network that enables the integrated lights communication system to accurately display safety conditions at the loading dock.

INNOVATIVE DESIGN AND OPERATION

- Vertical restraining range from 8” to 26” (203mm to 660mm) above grade with minimum 4” (102mm) contact space required

- A profile that is one of the lowest in the industry (8”/ 203mm), significantly reducing the risk of impact damage

- Horizontal restraining range up to 13” (330mm) from the face of the dock

- An Intelligent Positioning System (IPS) that does not use mechanical switches and sensors to detect the ICC bar, resulting in more dependable performance

- A high-visibility barrier-style restraint arm that uses passive engagement keep an ICC bar secured, resulting in less wear and tear and a lower lifetime cost of ownership

- PosiLock™ dual mechanical lock system that guards against accidental trailer separation and ensures safe, reliable performance during all stages of the engagement cycle

- Restraint arm dislodges or breaks apart obstacles that prevent it from properly parking

- Submersible: NEMA6 IPS sensor and double-acting hydraulic cylinders keep the unit operating safely and efficiently during wet or flooded conditions

INTELLIGENT TOUCH CONTROLS

- The Blue Genius™ Gold Series II Touch Control Panel features include an LCD menu screen, function buttons and a flat surface keypad with unique touch sensors

- Interior and exterior LED lights keep drivers and warehouse personnel advised of safety conditions

- Audible touch buttons and keypad provide instant sound feedback to user input

- Audible alarm built into the control panel alerts the dock attendant to potentially unsafe conditions, such as broken or missing ICC bars

StrongArm™ TL85

StrongArm™ TL85

The Blue Giant StrongArm™ TL85 hydraulic vehicle restraint keeps dock operations safe and secure during loading and unloading.

Trucks and trailers are held firmly in place by a high-visibility barrier-style restraint arm, and a restraining force of 32,000lbs (14,545kgs) prevents accidental separation from the loading dock during the cargo handling process.

The TL85 may be left engaged overnight to deter trailer theft.

non-impact operation

- ICC bars are secured via passive engagement, creating less wear and tear on the restraint components and consequently lowering maintenance requirements

- Internal automatic pressure switch maintains the arm in the locked position while in operation

- Compatible with air-ride suspension systems

- VersaLock™ securing technology allows the restraint arm to lock at any angle between 45 and 90 degrees

- Perfect for applications that involve a variety of truck configurations, including those with bent or damaged ICC bars

- Services trucks with ICC bars from 12″ to 26″ (305mm to 660mm) above ground

- Horizontal restraining range is up to 12″ (305mm) beyond the face of the dock

- Should an obstacle prevent the restraint arm from properly parking, the arm will dislodge it

versatile installation

- The TL85 comes standard with a remote, wall-mounted powerpack, but is also available with a self-contained powerpack, to suit site conditions

- May be wall or ground-mounted

intelligent touch controls

- The Blue Genius™ Gold Series II Touch Control Panel features include an LCD menu screen, function buttons and a flat surface keypad with unique touch sensors

- Interior and exterior LED lights keep drivers and warehouse personnel advised of safety conditions

- Audible alarm built into the control panel alerts the dock attendant to potentially unsafe conditions, such as broken or missing ICC bars

- Audible touch buttons and keypad provide instant sound feedback to user input

Electric Vehicle Restraints

StrongArm™ HVR303

StrongArm™ HVR303

The wall-mounted Blue Giant StrongArm™ HVR303 electric vehicle restraint secures a trailer to the loading dock via an electro-mechanical hook design. Easy to install and eco-friendly, the HVR303 combines advanced engineering, positive holding ability, and sophisticated touch controls to make your loading dock safer than ever before.

Instant Compensation Float

With a vertical restraining range of 9″ (227 mm) to 25″ (635 mm) and instant float of 16″ (406 mm), the HVR303 services a wide variety of trailers, including those with bent or damaged ICC bars. Ability to adjust automatically to trailer motion makes it compatible with air-ride suspension systems, enabling solid engagement and minimizing the risk of separation and worker injury.

Green Power

The StrongArm™ HVR303 is an environmentally sustainable alternative to oil-powered hydraulics. It can be interlocked with Blue Giant air-powered dock levelers to build a ‘green’ loading dock solution, allowing builders and developers to qualify for government incentives as well as project the image of an environmentally responsible business.

Strength You Can Depend On

With a restraining force of 32,000 lbs (14,545 kgs), the StrongArm™ HVR303 helps prevent the dangers associated with unexpected horizontal or vertical trailer movement. Secure gripping and holding capability enables a smooth and fortified bridge between the loading dock and the trailer, keeping cargo, equipment, and forklift operators safer during loading and unloading.

Designed to comply with ANSI MH30.3.

INTELLIGENT TOUCH CONTROLS

- The Blue Genius™ Gold Series II Touch Control Panel features include an LCD menu screen, function buttons and a flat surface keypad with unique touch sensors

- Interior and exterior LED lights keep drivers and warehouse personnel advised of safety conditions

- Audible alarm built into the control panel alerts the dock attendant to potentially unsafe conditions, such as broken or missing ICC bars

- Audible touch buttons and keypad provide instant sound feedback to user input

VIDEO

Mechanical Vehicle Restraint Systems

ML10 Mechanical Vehicle Restraint System

The ML10 is a manually operated mechanical vehicle restraint. It features a rugged structural design for reliable performance. It is easy to operate. The ML10 is easily installed and requires no electrical hook-up.

Blue Giant’s ML10 is an effective and economical way to enhance loading dock safety.

Non-Impact Operation

- Passive engagement style results in less wear and tear and lowers maintenance requirements

- With a vertical restraining range of 11″ to 26″ (279 mm to 660 mm) above ground and horizontal reach of 13″ (330 mm), the ML10 is compatible with virtually all modern trucks and trailers, even those with air-ride suspension systems

Holds Strong

- 30,000lbs (13,636kgs) of restraining force prevents premature truck departure during loading and unloading

- The unit can be left in the locked position overnight to discourage trailer theft

No Power Necessary

- Certain applications, such as chemical handling facilities or grain storage locations, involve explosive substances and require limited interaction with electrical devices:the ML10 is a safe and reliable restraining device for these situations because of its entirely mechanical operation.

The Next Level

- The ML10 system can be upgraded to include a manual or automatic lights communication package for added safety at the loading dock

- The TLC24-M has interior and exterior LED signal lights (red / green) that are manually controlled to communicate safety conditions to both dock workers and truck drivers

- The advanced TLC24-A has all the benefits of the TLC24-M but also detects the position of the restraint via a sensor, allowing the lights to automatically change according to the relevant safety condition

Additional Loading Dock Articles

New Dock Seals in Canastota, NY

We recently replaced all 10 dock seals for one of our favorite wire and cable customers in Canastota, NY. We tried to get a picture showing all 10 shiny new seals, but the delivery trucks [...]

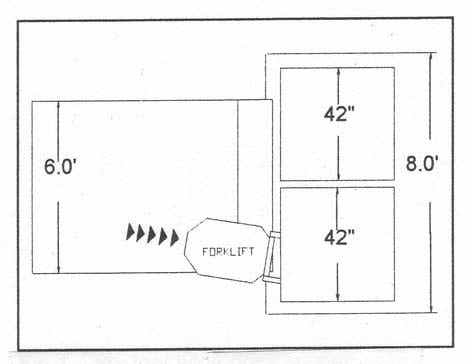

What Width Dock Leveler Do I Need?

How to Determine Proper Dock Leveler Width Dock Levelers and Width Selection Most all manufacturers now offer three standard widths for their mechanical, hydraulic, and pneumatic dock levelers. [...]

How to Calculate Loading Dock Leveler Capacity

How to Calculate Loading Dock Leveler Capacity Selecting the proper dock leveler capacity for a loading dock leveler can be confusing due to the variables that must be addressed. Dock leveler manufacturers have different [...]

How To Calculate Loading Dock Approach for Seals and Shelters

Last week I had a customer ask me how to properly calculate the grade of a declined dock approach to their loading dock. As I'm fairly certain they are not alone, I figured this [...]

Loading Dock Design and Planning – Series 2 – Dock Type

This is our second education series for Loading Dock Design. To visit the first module please click here for Loading Dock Design and Planning - Series 1. Dock Type Flush Dock Design Flush docks are [...]

Loading Dock Design and Planning – Series 1 – Access and Approach

Loading Dock Design and Planning Series 1 The proficient stream of products in and out of facilities is vital in today’s extremely competitive world. Special consideration must be given to the loading dock area [...]